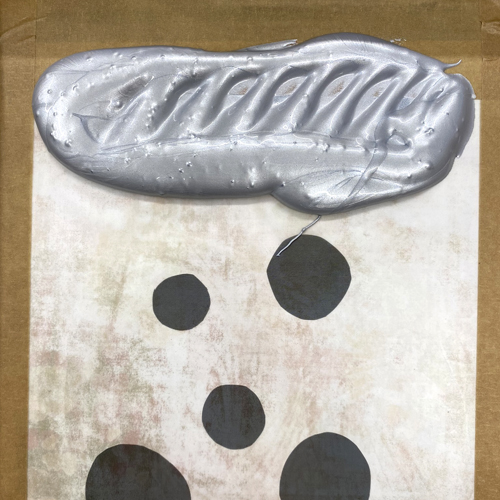

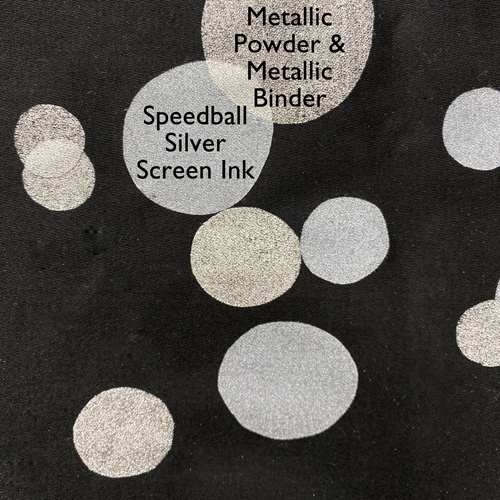

Printmaking with metallics can add a real pop to your designs. There are a few different options to choose from when screen printing with metallics: pre-mixed metallic ink, metallic powder and textile foils. We’ve made this project using all three methods to show you the advantages of each one.

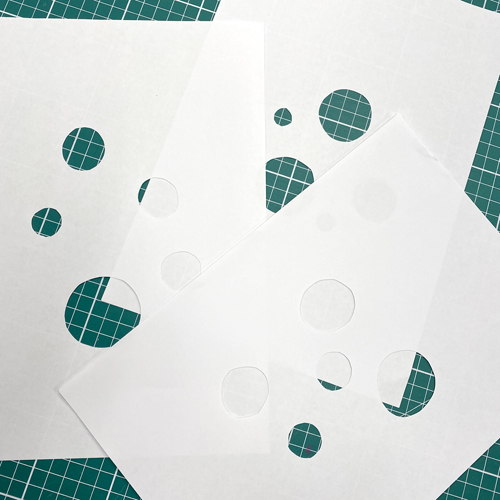

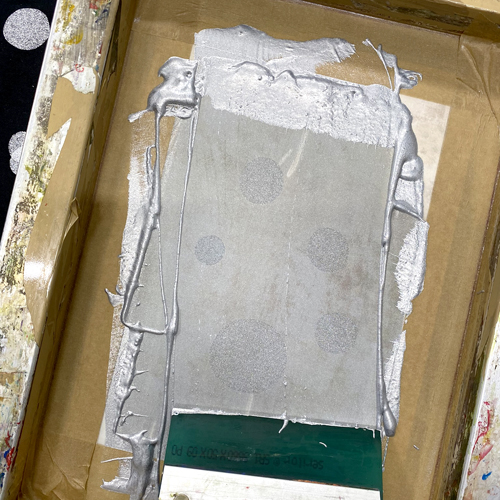

We cut three paper stencils: one for each type of ink in this project. This way, the stencil could be peeled off and the screen cleaned between each ink type.

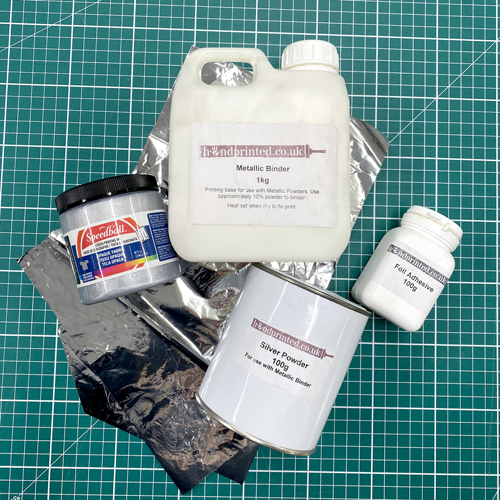

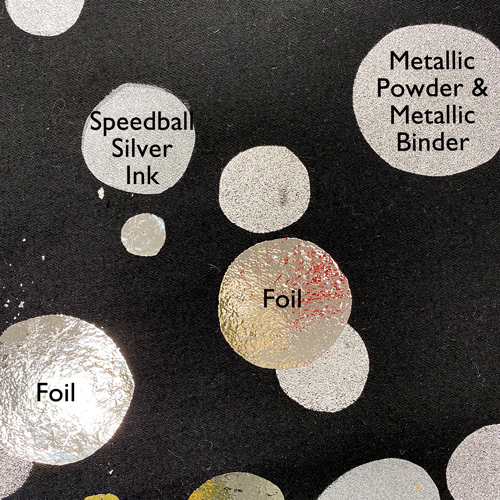

We are using three types of metallic screen printing: Speedball Metallic Screen Printing Ink in Silver (also available in gold), Metallic Binder mixed with Silver Metallic Powder (also available in gold) and Textile Foil (available in lots of colours).

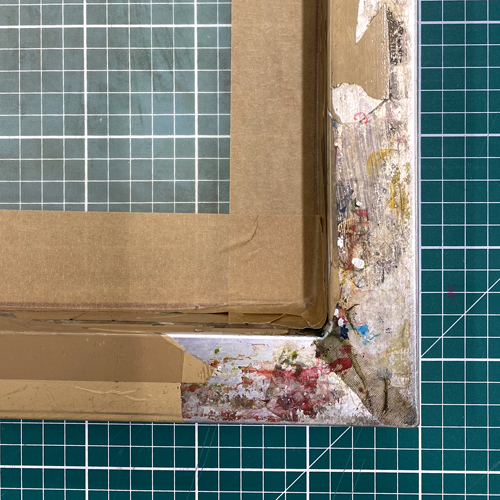

A 43T mesh screen is perfect for printing onto fabric.

Begin by taping the screen around the edges with parcel tape on both sides of the mesh. We used paper parcel tape. If using a paper stencil, make sure the aperture is slightly smaller than the paper.

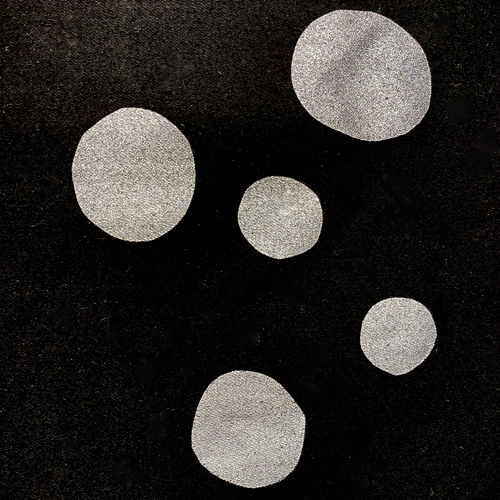

Speedball Opaque Fabric Screen Printing Ink in Silver is a pre-mixed ink that can be used straight out of the pot. It’s opaque so can be used to print onto both dark and light fabrics. We are printing onto black cotton.

Permaset also have metallic screen printing ink that will work beautifully too!

It has a beautiful metallic sheen.

Lay the fabric down onto a padded surface and pin it down in the corners. Lay the paper stencil on the fabric and the screen on top.

Place a line of ink at the top of the screen, above the design.

Use a squeegee at a 45′ angle to lightly drag the ink down the screen. This will flood the mesh with ink. Leave excess ink at the bottom of the screen. Place the squeegee back at the top of the screen and drag the squeegee down again at a 45′ angle, pressing hard this time. Use your other hand to hold the screen still.

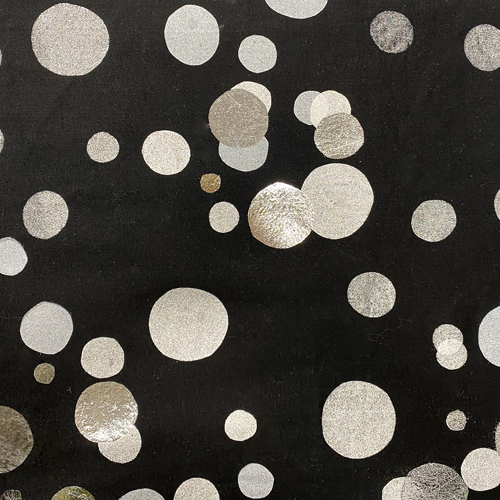

This ink shows up very well on black cotton. The finish has a soft metallic sheen. It washes well but will need heat setting before washing – heat set by ironing on a high heat until the print feels hot to the touch.

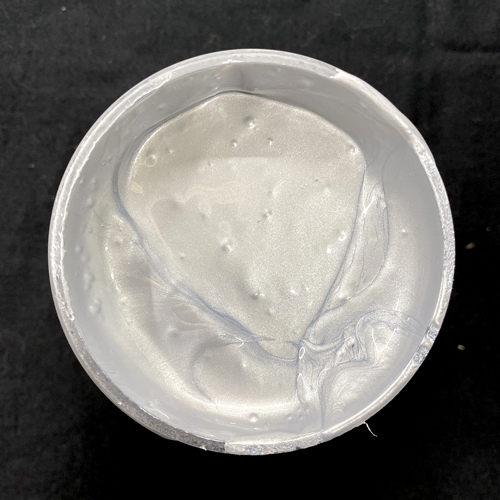

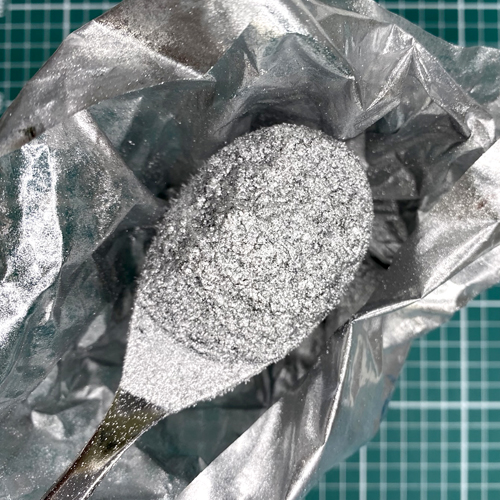

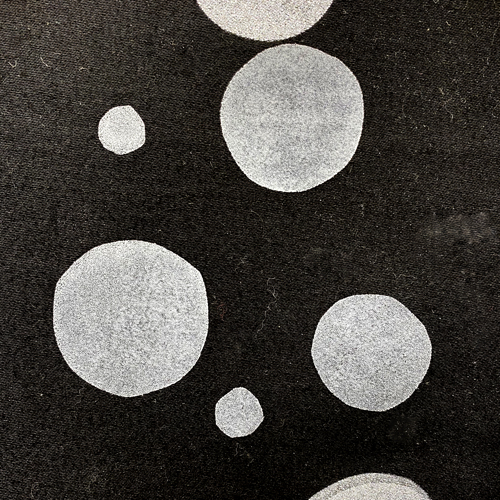

Our second metallic ink choice is Metallic Binder and Metallic Powder in Silver. These two are mixed together to create a metallic ink by themselves or with Pigment Colours to create coloured inks with a metallic shine.

The powder is very fine so it will not block the mesh. It’s made of aluminium and will not tarnish. It is advised to wear a mask when handling fine powders like this.

The powder and binder should be mixed together in a ratio of 1:10 powder to metallic binder. Less powder can be used for a less metallic finish. Pigment Colours could also be added to this mix to create various coloured inks with a metallic sheen.

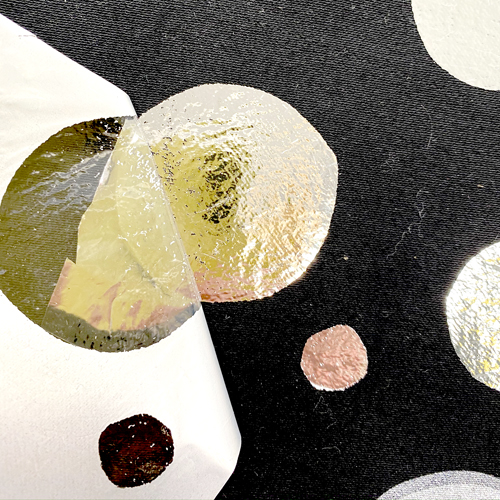

The finish of this ink is a slightly warmer grey than the Speedball ink. It also has a more glittery look because of the way the particles are suspended in the binder. It shows up very well on black fabric. Like the Speedball ink, it will need heat setting before washing.

Inks mixed with Metallic Powder and Binder are a bit less wash-friendly than pre-mixed inks. They’re more well suited to projects that won’t need washing as often, like decorations accessories or home furnishings.

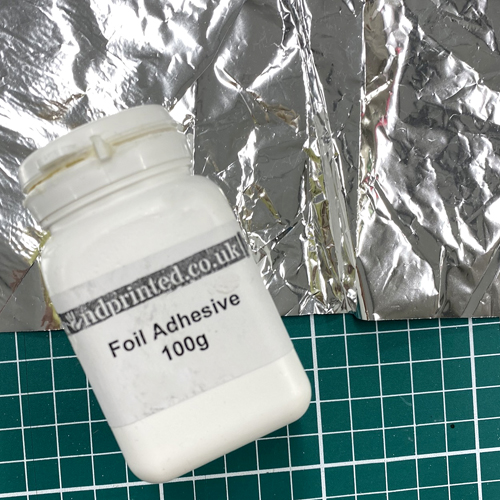

Our third and final metallic option is Textile Foil. For this technique, we need to apply Foil Adhesive to the fabric before using an iron to apply the foil.

Foil adhesive can be screen printed onto the fabric just like an ink.

The glue will look pale and matte on the surface of the fabric. When you have finished printing with the glue, wash the screen before applying foil.

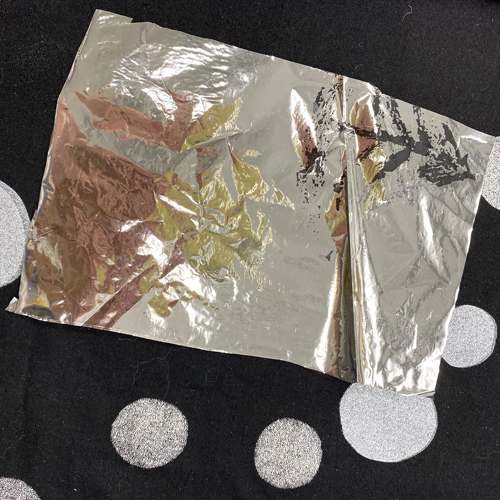

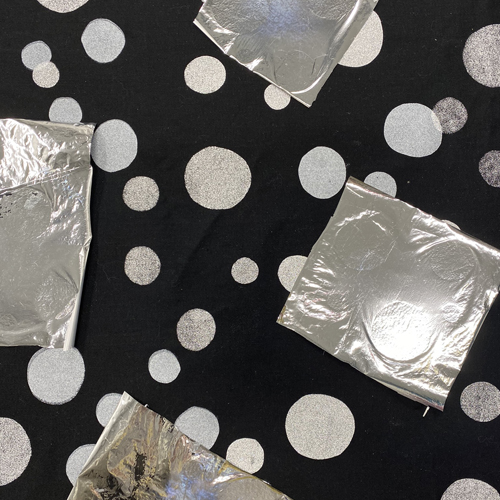

When the adhesive has partially dried (tacky – not wet, not dry), it’s ready to have foil applied. This usually takes between 10 and 15 minutes. Lay the foil shiny side up on the adhesive.

Cover with a piece of greaseproof paper and iron for about 30 seconds.

Leave the foil to cool on the fabric. This is important – warm foil won’t peel cleanly away from the fabric.

When the foil has completely cooled, peel away the excess.

Textile Foil is by far the most metallic option as a layer of foil sits on the surface of the fabric. It is slightly less hard-wearing than ink though so needs treating with care.

All three techniques create a beautiful metallic print on this black cotton. Textile Foil is the most metallic, then the Metallic Powder, with Speedball Silver Ink the least shiny but the most hard-wearing and washable.

With all these techniques, please make sure no ink or adhesive dries in the mesh by working quickly and washing it as soon as printing has finished. Once ink or adhesive has dried in the screen it’s very hard to remove it! Metallic inks and opaque inks tend to dry a little more quickly than standard inks.

For this project you will need:

- A4 43T screen

- Squeegee (225mm or 125mm)

- Parcel Tape

- Copy paper (for paper stencil)

- Scissors/scalpel and cutting board

- Spatula/spoon

- Fabric to print onto

- Iron

- Padded surface

- Pins

PLUS EITHER

OR

- Metallic Powder

- Metallic Binder

- Lidded pot for mixing ink

OR

- Foil Adhesive

- Textile Foil

- Greaseproof paper